Overview Of The Saw Blade

Posted by: pacvietnamCategory: News

Sawing is a technological step in the process of making products, mainly in the process of creating embryos and processing burr.

Each material will need a different specialized saw blade, basically more teeth will give a smoother cutting surface, and vice versa, the serrated is rougher.

Some forms of saw blade:

-

- Un-coated saw blade(white): Ideal for cutting non-ferrous metals such as brass, aluminum etc.

- Slightly ground saw blades (black): there is a layer of ferric oxide on the surface, giving the saw blade a longer tool life.

- Glossy Chromium-coated saw blade: there is a thin layer of chromium on the surface, protecting the saw blade from rust and adhesion.

- TiN coated saw blade: When cutting pipes and shaped steel, allow cutting at higher speeds.

- TiAlN coated saw blade: TiALN coating protects saw blades at high temperatures better than TiN, so this type is ideally used at high temperatures caused by cutting at high speeds or cutting hard materials.

- TiCN saw blade: TiCN coating has a friction coefficient smaller than TiN. They are used for all types of steel, including stainless steel

- CrN saw blades: CrN coatings have a low friction coefficient, used to cut non-colored metals that allow for longevity.

Saw blade application:

-

- Application for cutting steel with a thickness of <6 mm: The characteristics of steel are relatively thin, soft thickness so the cutting of steel with an alloy disc saw blade is the easiest, the speed of cutting is about 1500 rpm. Usually the machine used for this type of blade is a small portable cutting machine (similar to a conventional stone cutter but at a slower speed).

- Solid stainless steel cutting application or solid steel monolithic or round >6 mm: Use coated HSS blade or carbide tip with coating blade with in combination with a fixed machine with a cooling system. Cut at a slow speed of 50-100 rpm. For large companies, using alloy saw discs combined with CNC automatic cutting machines with large sizes, fast cutting speed from 150-800 rpm, average disk life from 3000-5000 cuts.

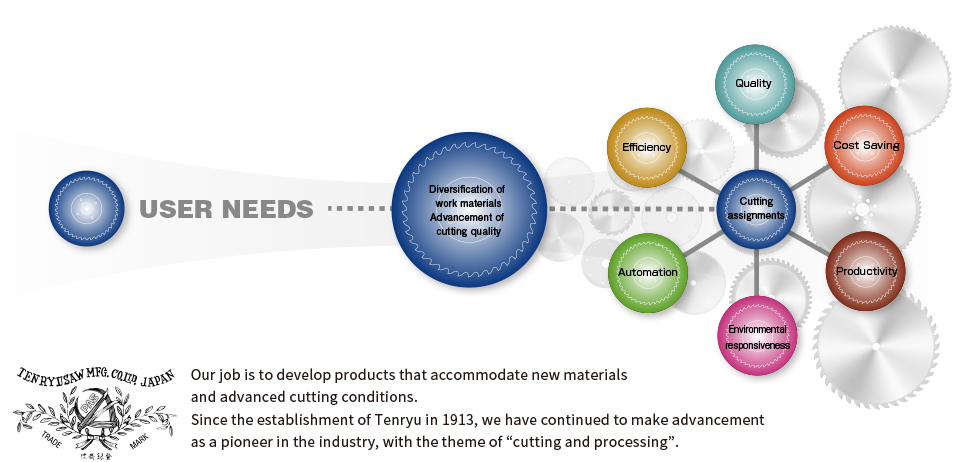

Tooltech Vietnam Technology JSC is currently a distributor of TENRYU’s quality saw blade product line in Vietnam.

For any question you may have:

TOOLTECH VIETNAM TECHNOLOGY JOINT STOCK COMPANY

Add: Room 1016, Building N02, Tran Quy Kien Street, Cau Giay District, Hanoi, Vietnam

Office: 2nd Floor, Tower B, Building T608, Co Nhue Urban Area, Co Nhue 1 Ward, Bac Tu Liem District, Hanoi, Vietnam

Email: support@tooltechvietnam.com/ assistant@tooltechvietnam.com

Hotline 0961 576 069 (Zalo)-Ms Ngoc

Tel: +84-24-3207-2525 Fax: +84-24-3207-3535